Cerafab System S65 3D printer for medicine

Lithoz is committed to providing the medical and dental industries with only the highest quality technology and services. The new CeraFab System S65 Medical facilitates the production of the highest quality 3D printed components with outstanding biocompatible properties and virtually limitless geometries. From patient-specific implants to mass customization, from medical to dental, imagination is the only limit. The state-of-the-art CeraDoc software allows you to easily and automatically document the production of medical devices, providing full traceability and easy data analysis. Tool-free LCM technology means CAD data can be modified to suit specific patient needs

- Cerafab medical 3D printers are operated in Europe, North and South America

- Obtained CE medical device certification (Class III) and FDA approval (Class IIa)

- Since 2017, more than 20 operations have been performed using implants produced using LCM technology

- Medical bioceramics

- Medical devices and individual implants for a specific patient

- Metal-free solutions for dental procedures

Cerafab System 3D printers

ndustry-leading and reliable 3D printers designed for scalability and ready for advanced development and mass production.

The CeraFab System family is the best choice for industrial batch production of high quality ceramics using additive manufacturing. Each machine in the CeraFab System family of S25, S65 and S230 offers a complete 3D printing system for advanced designs. A total of four production units can be combined, making it easy to scale up and quickly produce exceptional ceramic components. From small batch production to large scale production, these machines can complete all types of high quality 3D printing projects due to different build volumes and have the fastest 3D printing speed on the market.

The current generation of projectors with WQXGA resolution, combined with a specially developed technology lens for this purpose, ensures the absolute accuracy of printed components - even in the micrometer range.

Lithoz is a leading technology provider and trusted partner for high-performance ceramic components and the development and production of a variety of materials.

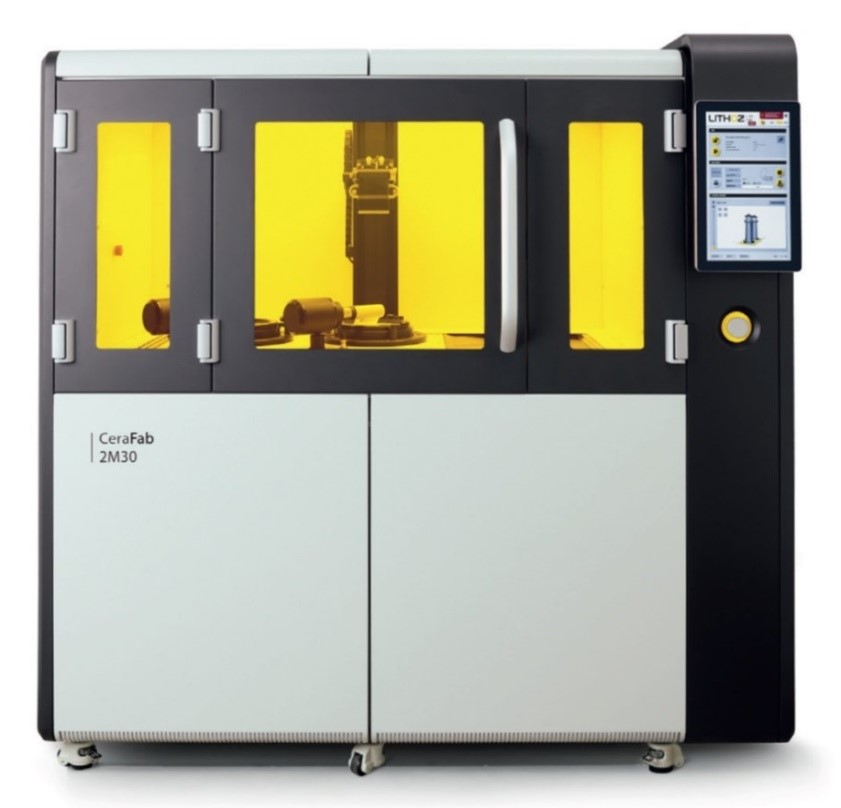

Cerafab Multi 3D printer

An innovative development for the production of components from several materials printed on a 3D printer.

The latest breakthrough, CeraFab Multi 2M30, brings the idea of 3D printing complex geometries from multiple materials. With this 3D printer, it is possible to combine not only ceramics, but also metals and polymers, which contributes to the gradual change in the composition and organization of materials within a component. The open system allows you to develop your own materials, and now you can produce multifunctional components that are not possible with conventional molding technologies. Designers can integrate additional processes (eg inkjet printing, coating) to extend the CeraFab Multi 2M30’s range of capabilities for even more complex applications.

HEAVY DUTY QUADRO

3d scanner ready to work in the workshop and in adverse environments. Accurate 3D scanning of medium to large objects in harsh environments

- Accuracy certified according to VDI / VDE recommendations

- four cameras 5 Mpix

- two scan ranges in one block

- dustproof device (IP62)

- designed for industries and all types of production lines

- ideal for: quality control, reverse engineering and rapid prototyping

The first 3D scanner ready to scan in almost all conditions. With this device, 3D scanning is possible outdoors or in harsh environments. With two variable scan ranges, it allows you to scan medium to large objects. With its four 5 megapixel cameras, this scanner is a very versatile and professional device. Heavy Duty Quadro is a 3D solution ideal for scanning service organizations that design and manufacture items that require quality control, reverse engineering and rapid prototyping.

HEAVY DUTY BASIC

Precise 3D scanning of middle elements in all kinds of materials

- Blue LED projector

- Accuracy certified according to VDI / VDE recommendations

- Two 1.3 megapixel cameras

- Dedicated solution for science and education, research and development departments

- Ideal for: Quality control, reverse engineering and rapid prototyping

The first 3D scanner based on blue LED technology, which is available to almost everyone. It is the only device on the market that provides high accuracy at an affordable price, not only for industry, but also for education, research departments of small and medium-sized enterprises.

This device is revolutionary in professional 3D scanning. Heavy Duty Basic provides professional 3D scanning technology. Discover 3D scanning in reverse engineering, optical quality control and rapid prototyping. See things bigger with eviXscan 3D solutions!

HEAVY DUTY OPTIMA

- Blue LED projector

- Accuracy certified according to VDI / VDE recommendations

- Two 5 megapixel cameras

- Low power consumption (20W)

- The Heavy Duty Optima is ideal for companies where high measurement accuracy is a key factor for the customer and they want to maintain this performance despite the small budget available.

- Applications: reverse engineering, quality control and rapid prototyping

eviXscan 3D Heavy Duty Optima is a professional reverse engineering tool for 3D scanning, non-contact quality control and rapid prototyping of medium sized models.

Optima is an optimized combination of key parameters for the customer: high precision measurement (up to 0.0183 mm), high dot density (95 pt/mm²) and large scan volume (250 mm x 170 mm x 120 mm), all at an affordable purchase level and implementation of an integrated measuring system.

The Heavy Duty Optima is ideal for companies where high measurement accuracy is a key factor for the customer and they want to maintain this performance despite the small budget available. The Heavy Duty Optima is equipped with two high-quality 5MP cameras and a powerful blue LED light source, keeping power consumption low (20W) and reducing heat dissipation while extending product life. The advantage of a specific wavelength of the light source helps to limit the influence of the optics on the collected data, with blue light having the lowest diffraction, helping to keep measurements at the highest level.

APPLICATION EXAMPLES

- measurement of hard-to-reach objects

- creating all kinds of 3D renderings

- reverse engineering of elements without CAD documentation

- measurements of deformed / welded elements and comparison with the CAD model

- quality control of manufactured parts