Purpose of installation:

- Single-pass welding in vacuum along various trajectories.

- The equipment provides welding:

- Steel alloys up to 65 mm thick;

- Titanium alloys up to 70 mm thick;

- Aluminum thickness up to 80 mm;

- Carrying out local heat treatment and welding.

ELSE ADVANTAGE:

- Efficiency

- Wide range of processed materials

- Minimum warping

- Integration into production lines

- No filler material required

- No inert medium required

- Innovation in design

- Creation of dissimilar materials (bimetallic compounds)

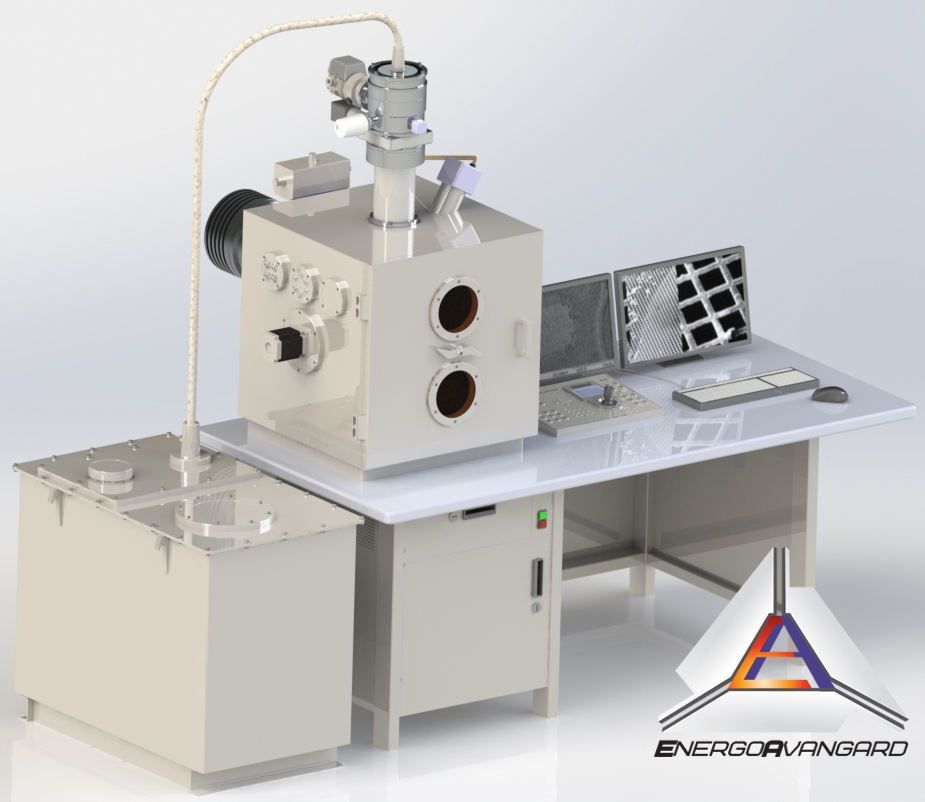

COMPLETE EQUIPMENT:

- Control box

- Remote control panel

- Vacuum chamber

- Vacuum system

- Electron beam gun

- The mechanism for moving the workpiece

- Surveillance system

- Spare parts

Electron-beam installation for microwelding

In the development of ELP, two technologies are combined into one whole: obtaining a high-quality raster image in secondary and reflected electrons (SEM) and a balanced three-electrode scheme of electron beam welding, which is common to both devices and consists of a cathode-anode block and a control electrode. The crossover calculation was carried out and optimized taking into account the features of beam formation for both optoelectronic systems.

Due to the properly balanced configuration of these elements and the focusing system, it is possible to achieve a beam diameter at the welding point of 15 µm.

For stable operation of the gun, it uses differential dry pumping by a separate turbomolecular pump and a vacuum control sensor in the cathode-anode block. ELP is equipped with electromagnetic raster centering, stigmatizing and focusing systems, a reflected electron detector with coaxial placement.

A secondary electron detector with a tilt angle of 45 degrees is installed in the chamber, as well as a coaxial video surveillance system for the workpiece in the same direction as the electron beam, which ensures observation of the welding process at low welding currents.

The ELP provides for operation with two types of cathodes: V-shaped (tungsten) or LaB6 (lanthanum hexaboride). The design of the gun allows you to quickly change the cathode units within 2-3 minutes due to the preliminary alignment of the cathode in the block using special technological devices.

High voltage power supply 60 kV / 2 kW

The installation is equipped with systems that allow to work in the mode of a scanning electron microscope (SEM) to obtain in real time the surface of the welded products with a high resolution of up to 15 microns. This allows for positioning and welding with very high precision.

To obtain an SEM image, the setup is equipped with two detectors of secondary and reflected electrons. One detector (reflected electrons) is installed at the end of the gun, the second - on the wall of the vacuum chamber (see Fig. 11). This arrangement allows you to optimize the contrast of the part image. High image quality (Fig. 12,13,14,15) is provided by a two-lens focusing system and a low-noise amplification path used in SEM.

The SEM mode has a fast sweep mode of 250 x 250 points for real-time operation and a high resolution mode of up to 2000 x 2000 points. The operator uses these modes according to the situation. Fast - for preliminary positioning of the product and high resolution - for detailed viewing of the surface of products with high resolution. The high resolution mode can be used for welding quality control and defect detection.

Vacuum system

The vacuum system consists of two independent systems controlled by one system for controlling the operation of actuators. One system ensures the production of vacuum and its control in the vacuum chamber, the second - in the cathode-anode block of the gun. The pumping systems consist of a dry fore pump and a turbomolecular pump of appropriate capacity.

Vacuum fittings (gate, valve, actuator) are built on pneumatic actuators. The system includes a compressed air compressor that provides automatic control of the pressure in the pneumatic system. There is a vacuum shutter between the chamber and the gun, which allows for independent air inlet into the gun or chamber. Vacuum sensors are installed at control points to control the vacuum level.

Powder 3D printer

The technology of electron beam melting (EBW) is used. The technology is based on the melting of metal powder in a chamber with the formation of successive layers that follow the contours of a digital model.

- Adaptive materials: stainless steel, titanium, etc.

- Product Density: ≥95%

- Product Strength: Not inferior to similar products obtained by casting.

- Size: 200 200 *200mm (LW*H)

- Accuracy: ±0.2mm

Wire 3D printer

The technology of production of arbitrary shapes by electron beam melting (EBF3) is used. The technology is based on the melting of a bar in a chamber with the formation of successive layers that follow the contours of a 3D model.

- Adaptive materials: stainless steel, titanium, etc.

- Product Density: ≥95%

- Product Strength: Not inferior to similar products obtained by casting.

- Printing speed: 1 kg/hour

- Wire diameter: Ø 0.5 -2 mm