Presses for elastomers

Vacuum chamber Ejection system Mold control/mould maintenance Fully automatic application of release agent to facilitate demoulding of products from molds Complete solutions for clean rooms for the production of pharmaceutical products Completion of a cooling system Process control in the production of membrane layers Completion of presses with automatic modules, such as as loading / unloading, material supply, mold cleaning and process robotization

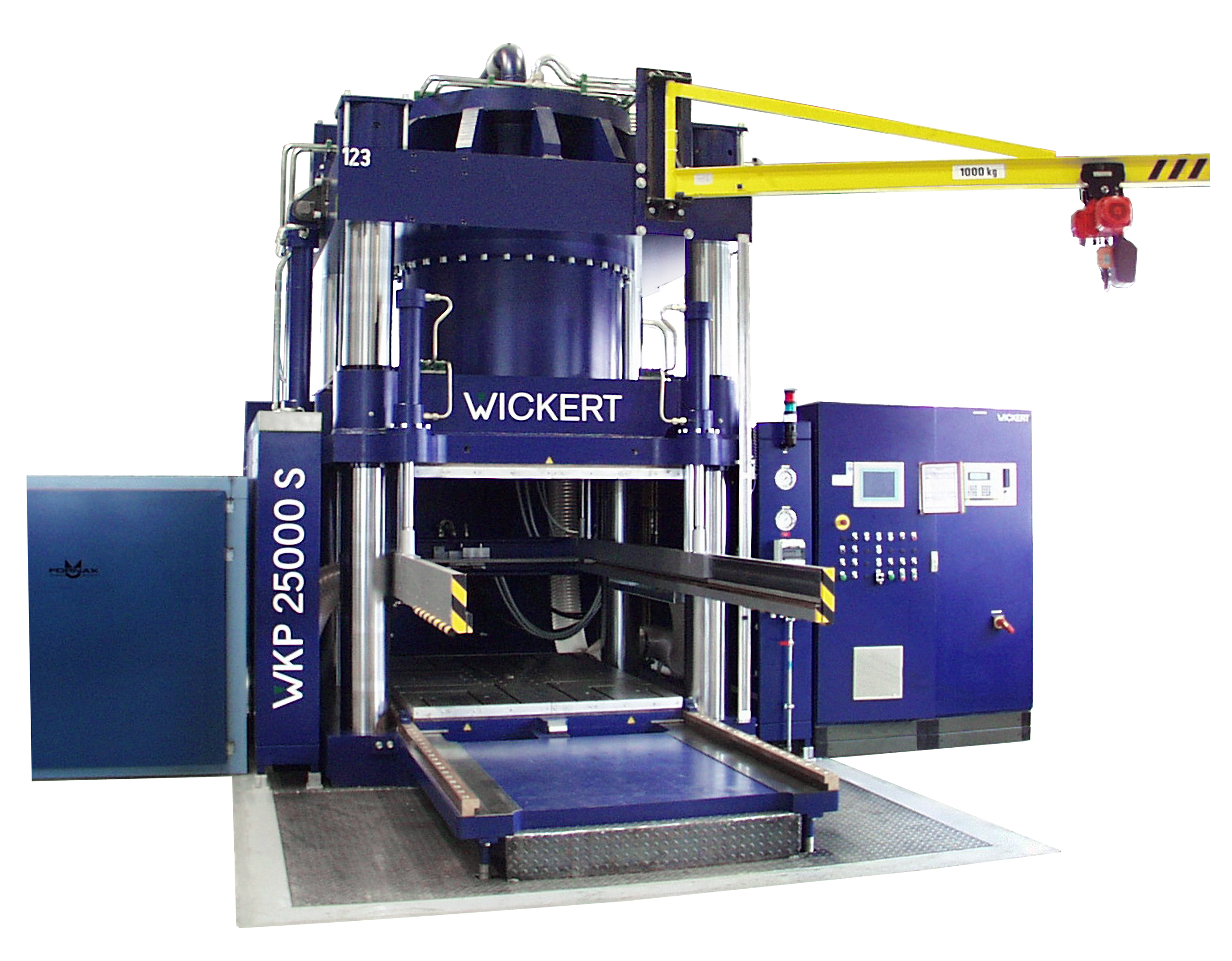

Hydraulic Presses and Fully Automated Pressing Systems for Elastomeric Materials (RTI)

The WICKERT presses of the WKP S series are specially designed for the production of molded elastomer parts according to the needs of the customer. The flexible modular design easily meets a huge range of compression, injection molding and injection molding requirements. WICKERT is the right partner for fully automatic press systems as well as simple manual presses.

Examples of presses for elastomeric materials (RTI)

- Press for the production of high-precision products from elastomer materials (RTI)

- Press for the production of large products from elastomer materials (RTI)

- Press for the production of pharmaceutical products from elastomeric materials (RTI)

Presses for composites

Hydraulic Presses and Fully Automated Pressing Systems for Composite Materials

It is possible to adapt the WICKERT press of the WKP S series for the production of composite materials to the required technical requirements. The design of the presses for each application can vary from a fully automatic pressing system to simple manual presses. The following processes for the production of various materials (GRP GFK decking, SMC and BMC materials, carbon and fiberglass fibers) can be implemented:

- RTM and HP-RTM processes

- thermoforming

- Compression pressing

- Prepreg pressing

- Pre-pressing

Presses for plastics and thermoplastics

Hydraulic presses and fully automated pressing systems for plastics and thermosets

WICKERT designs and manufactures state-of-the-art hydraulic or electrically driven presses for the plastics industry. The modular design on which our presses are based means that individual modifications to the press design can be made to meet specific customer needs. The wickert press is suitable for the following materials and processes:

- Polypropylene and polyethylene (PP, PE)

- High temperature thermoplastics (PPS, PEEK)

- Production of semi-finished plates from thermoplastic materials up to 6500×3000 mm in size

- Thermosetting plastics (free-flowing and low-flowing)

- BCM, SMC, BCMi

Presses for laboratory applications

Multi-zone heating system, thanks to which the accuracy of temperature distribution is ± 0.2 ˚С Isothermal and non-isothermal heating systems with electric, steam, water or oil heating Temperature change up to 50 ˚С/min Vacuum systems up to 1 mbar High temperature models with heating up to 500 ˚ From and above Wide range of special software for a range of industry solutions, e.g. for the rubber industry Data acquisition and archiving systems including connection to an office workstation Temperature accuracy according to DIN ISO 2392

Hydraulic presses and fully automated pressing systems for laboratory applications

The WICKERT WLP S series presses are specially designed for use in the laboratory. Thanks to the intelligent modular design, these presses can be easily adapted to your specifications.

Presses for powder materials

Hydraulic presses and fully automated pressing systems for powder materials WICKERT manufactures hydraulically or electrically driven automatic presses and pressing systems for the production of a wide range of powder materials. Due to the modular design, these presses can be modified to suit specific customer needs.

Presses for brake pads and clutch discs

Hydraulic presses and fully automatic pressing systems for brake pads and clutch linings WICKERT’s variable modular design allows for customized production of brake pad and clutch lining presses, as well as integrating presses into existing manufacturing processes. Brake pads are manufactured using cold and hot pressing methods. WICKERT also sells fully automatic systems for hot fixing wet clutch linings.

Abrasive presses

Hydraulic presses and fully automated pressing systems for abrasive materials The modular design of the WKP presses serves as the basis for the development and production of universal presses for cold and hot pressing. Our presses are capable of producing all types of grinding discs, such as diamond and boron nitride (CBN) discs, as well as ceramic and resin bonded discs.